中 国

EN

- Food and beverage industry

- Electronics and Semiconductors

- petrochemical industry

- Biopharmaceutical Medical

- Pneumatic conveying - dense phase

- Solar photovoltaic materials

- Battery materials

- Chip packaging testing

- PCB board

- Compressor remanufacturing

- Trade in the old

- lease

- Upgrades and optimizations

- Case

- training

- Maintenance

- Conservation

- data analysis

- consultation

- Download

- Progress inquiry

- report

- Food and beverage industry

- Electronics and Semiconductors

- petrochemical industry

- Biopharmaceutical Medical

- Pneumatic conveying - dense phase

- Battery materials

- Chip packaging testing

- PCB board

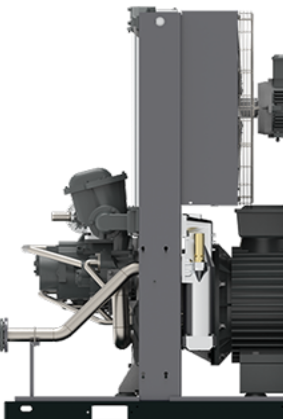

- Oil free Air compressor

- Oil free Nitrogen compressor

- Oil Free Argon compressor

- Oil Free Booster

- Portable Oil Free Air Compressor

- master

- end

EN

- Company Profile

- Job

- Partners

- Contact

- Team

NAPU

Diversity of Technology

Suitable for various methods and application fields

NAPU Dry oil-free twin-screw air compressors are widely used in electronics and semiconductors, food and beverage, biotechnology and pharmaceuticals, energy and chemical, and high-end manufacturing industries. With reliable quality and an extended warranty commitment, they have gained high recognition from users. Napu Compressor's vision is to continuously provide users with improved productivity, and we look forward to working with you!

service content

Product Consultation

Provide patient and meticulous product and technical consultation to customers, and offer professional selection and technical solutions based on their usage characteristics and requirements.

On site technical support

Provide customers with face-to-face professional technical support, application suggestions, and solutions; The customer is debugging on site and needs support when encountering difficulties in the application. We will arrive at the site as soon as possible to assist and ensure the progress of equipment debugging and normal use.

CLASS 0 Industry standards

Oil free air is applied in various industries where air quality is crucial for final products and production processes, including food and beverages, pharmaceuticals, petrochemicals, semiconductors and electronics, healthcare, automotive sprinklers, textiles, etc. In these harsh application scenarios, even minor oil stains can cause production stoppage or product damage.

NAPU starts with customizing compressor systems according to needs.

NAPU provides customized solutions with unparalleled classification and flexibility.

The main driving force behind it has always been the pursuit of sustainable solutions with significant added value, whether for our customers or for the environment.

The groundbreaking achievements we have made since 2005 have had a decisive impact on our advancement of air compressor technology, and it is by no means accidental.

Eliminate all risks

As an industry leader committed to meeting the most demanding requirements of customers, Napu Compressor invites renowned T Ü V testing agencies to test oil-free compressors. T Ü V used the strictest testing methods to detect all possible forms of oil over a wide temperature and pressure range, and no traces of oil were found in the output airflow.

Food and beverage industry

■ Provide 100% pure oil-free air for various applications (such as fermentation, packaging, aeration, transportation, canning and sealing, cleaning, instrument air supply).

■ Through ISO 8573-1 CLASS 0 (2010) certification, there is no compromise on the purity of the final product, ensuring no risk of contamination.

Electronics and Semiconductors

■ Producing clean, dry, and high-quality air with optimal energy efficiency is extremely important.

■ Applications include removing small debris from the motherboard on the surface of computer chips

petrochemical industry

■ Certified 100% oil-free and reliable compressed air is crucial for maintaining continuous production operation.

■ Being able to operate under extreme temperature and humidity conditions, high performance and reliability are essential.

Biopharmaceutical Medical

■ 100% oil-free air is crucial for preventing process pollution, such as fermentation, aeration, tablet coating, packaging and bottling, and automated production lines.

■ Class 0 eliminates all risks and maintains the high quality and professional brand reputation of the product.

Pneumatic conveying - dense phase

■ The lowest energy cost accounts for up to 80% of the lifecycle cost of the compressor.

■ With innovative single-stage screw compression technology, it minimizes downtime and reduces maintenance costs to the greatest extent possible.

Solar photovoltaic materials

■ Provide 100% pure oil-free air for various applications.

■ Compliant with the ISO8573-1CLASS0 certification standard, there is no compromise on the purity of the final product, ensuring no risk of contamination.

Battery materials

■ Producing clean, dry, and high-quality air with optimal energy efficiency is extremely important.

■ The application includes removing small impurities on the surface of materials.

■ Certified 100% oil-free and reliable compressed air is crucial for maintaining continuous production operation.

■ Being able to operate under extreme temperature and humidity conditions, high performance and reliability are essential.

Chip packaging testing

■ The lowest energy cost accounts for up to 80% of the lifecycle cost of the compressor.

■ With innovative dry screw oil-free compression technology, downtime is minimized and maintenance costs are reduced to the greatest extent possible. Wide flow and pressure range.

PCB board

■ Improve energy efficiency and productivity, and reduce environmental impact.

■ With innovative low-pressure dry oil-free screw compression technology, downtime is minimized and maintenance costs are reduced to the greatest extent possible.

Shanghai NAPU Compressor Technology Co. Ltd.

No. 3238, Shanghai Hangzhou Highway, Fengxian District, Shanghai, China

+86 21 58387871

www.napucompressor.com

info@napucompressor.com

Legal and Privacy Declaration Settings 2024 Copyright: Shanghai Napu Compressor